Wireless Form Tie Load Monitoring Custom Technology

Custom Technology

- Each Smart Pour Cell comes with its own Sentinel that is LTE / WiFi / Lora enabled and internal power supply.

- Connects seamlessly to the SmartPour app and cloud service.

Easy Integration

- Reliable, efficient, and patent-pending solution that’s easy to implement

SmartPour provides critical insights into the concrete placing process, helping avoid costly errors and delays.

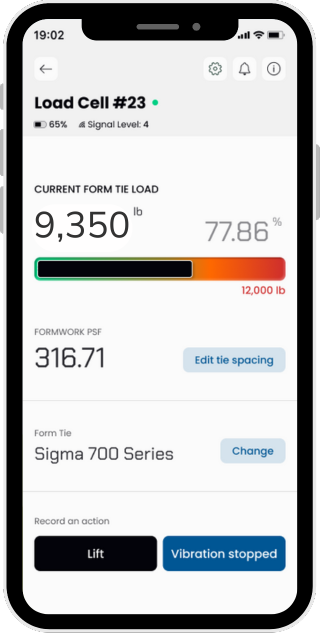

Real-Time Pressure Monitoring

- Instantly measures form tie loads to enable safer concrete placement.

- Helps detect the effects of vibration on formwork pressure and tie forces.

Actionable Insights

- Reduces the risk of blowouts and form panel bowing

- Maximize safe concrete placement rates and increase on-site productivity.

Improved Safety & Efficiency

- Reduces the risk of blowouts and form failures.

- Enhances on-site productivity and allows syncing truck deliveries to the pace of your project.

Simplified Data Integration

Formwork suppliers often derate allowable form pressures (PSF) to account for a variety of factors. SmartPour can easily display the current form pressure (PSF) from a few user inputs to help eliminate guesswork during placement, allowing the user to stay within the requirements of the stamped formwork drawings.

How To Use SmartPour

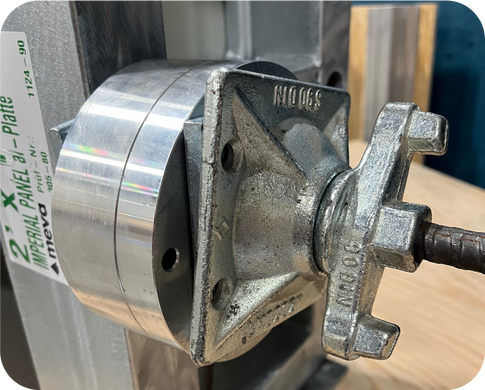

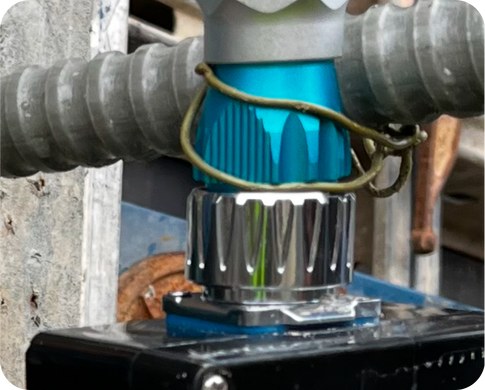

Install SmartPour

It simply fits over the form tie sandwiched between two bearing plates

Connect Sentinal to the load cell

Plug the SmartPour Cell into the Sentinel. This provides the power to the SmartPour Cell. This connection shows the SmartPour Sentinel connection secured by tie wire to the end of the form tie. This method of securing the Sentinel away from the form work is acceptable.

Turn on and wait for the green light

The green light means that the cell connection is properly established . Ensure more than 50% battery life and good cell signal via the app.

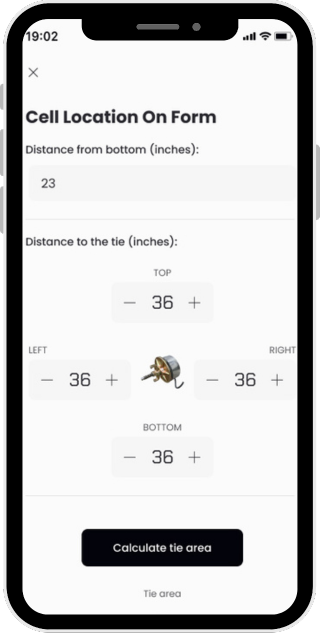

Connect the SmartPour Cell to the app

Choose the form tie style, verify its safe working capacity, and enter the distance to the next closest tie or form edge in each direction to accurately calculate form pressure (PSF). At the top of the Cell Location screen, enter the distance from the bottom of the form to the SmartPour load cell. If more than one load cell is used, enter this information for each load cell.

Start monitoring!

Load will begin to register after 500 pounds has been reached and will increase in increments of 50 pounds.

Products

The Sentinel + 40 KIP Load Cell

The Sentinel SmartPour System combines advanced connectivity with precision load measurement. The Sentinel Hub powers the SmartPour Load Cell, providing cellular, Wi-Fi, and LoRa connectivity with up to 3 days of battery life. The SmartPour 40 KIP Load Cell handles loads from 5,000 to 40,000 pounds with accuracy, The 60 kip cell has a 1.5” center hole diameter. This system is scalable for future concrete curing sensors and real-time monitoring needs.

The Sentinel + 60 KIP Load Cell

The Sentinel SmartPour System combines advanced connectivity with precision load measurement. The Sentinel Hub powers the SmartPour Load Cell, providing cellular, Wi-Fi, and LoRa connectivity with up to 3 days of battery life. The SmartPour 60 KIP Load Cell accurately handles loads ranging from 20,000 to 60,000 pounds, The 60 kip cell has a 1.5” center hole diameter. This system is scalable for future concrete curing sensors and real-time monitoring needs.

SmartPour utilizes patent-pending technology that represents the forefront of innovation in load cell systems. Its advanced design integrates cutting-edge connectivity, precision engineering, and proprietary features, ensuring unmatched performance and reliability. The unique combination of wireless capabilities, durable construction, and seamless integration with long-range sensors makes it not only highly effective but also nearly impossible to replicate. SmartPour’s state-of-the-art system sets a new industry standard, providing users with a competitive edge and a solution built for the future.